Types of Pumps In the Oil and Gas Industry

Types of Pumps in the Oil and Gas Industry

Pumps are invaluable fixtures on many oil drilling rigs. This equipment accelerates the fluid transfer from one location to another. Refineries need these pumps because oil displacement is critical for rig operations. Processing fluids in the gas and oil industry can be challenging, and using the correct refinery pumps will aid the process. In this guide, you’ll discover various oil pumps and their applications.

Types of Oil and Gas Pumps and Their Applications

Many oil well pump types streamline the fluid displacement process, whether delivering oil to a storage facility, refinery or ship. Along with carrying oil, the various pump types operate under similar principles, allowing you to find the best one for your application.

Each pump has a distinct function and can ease daily operations, so choosing the correct one will be vital for your business. Below, you can discover all the information you need about how oil pumps work and their various applications.

Centrifugal Pumps

Centrifugal pumps for the oil and gas industry use one or multiple rotating impellers to suction the oil into the pump before discharging the fluid with centrifugal force. Valves control the discharge.

These pumps are excellent for low-viscosity fluids with high flow rates and do not contain fumes, air or significant amounts of solid particles. Often, you will use these pumps within a more extensive network for secondary gas and oil recovery or oil shipping. You may also add an electric submersible pump, which separates oil and water to re-inject the water into a reservoir without bringing it to the ground surface.

Metering Pumps

Metering pumps transfer an exact fluid volume within a specific time at an accurate flow rate. Delivering liquid with these adjustable, precise flow rates is a practice known as metering. Rather than describing a particular type of pump, a “metering pump” can change depending on the use or application. Many metering pumps are reciprocating pumps with a diaphragm or packed plunger end. Diaphragm ends are the better choice because they seal fluid inside, preventing it from leaking into the atmosphere.

Diaphragm Pumps

This industrial oil pump has a diaphragm and valve to draw gas and oil into a refinery chamber during the midstream and upstream refinement phases. As the chamber volume increases, the pressure decreases, allowing fluid to pour into the chamber. Then, the diaphragm pushes the oil out as it moves up and down. After the liquid clears the chamber, the diaphragm will adjust to allow more liquid to enter.

These pumps’ unique design allow you to move large amounts of fluid. Diaphragm pumps are excellent for refineries with access to sizable oil sources. The small number of friction points or moving parts in these pumps makes them wear-resistant, as the components are less likely to break down. However, they can experience brief changes in fluid output called winks, which can slow the pumping operation.

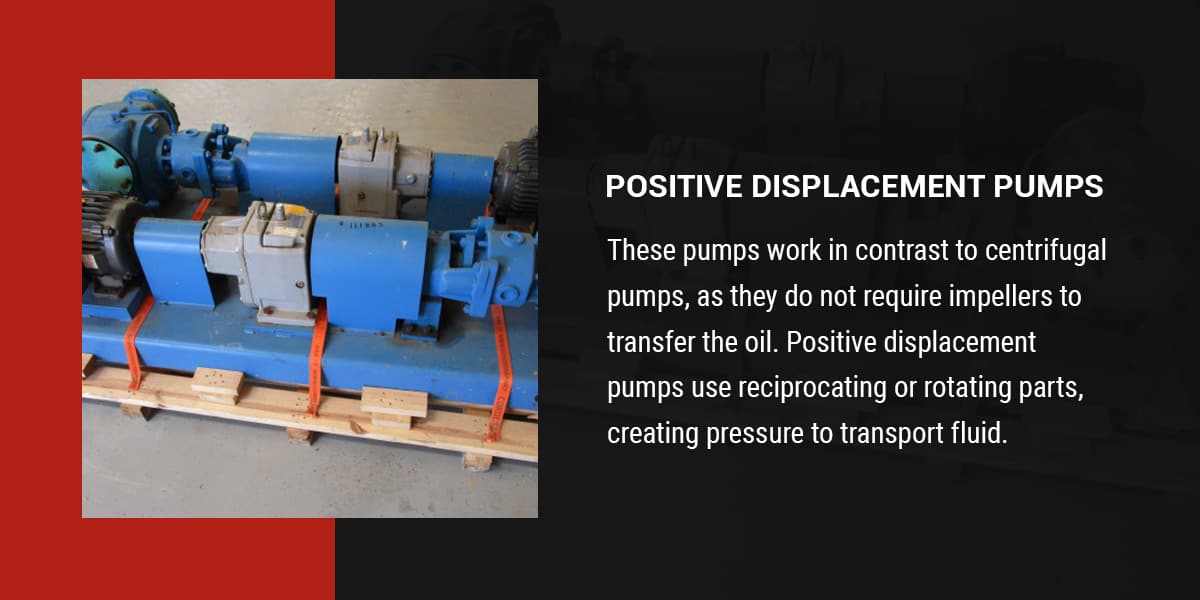

Positive Displacement Pumps

These pumps work in contrast to centrifugal pumps, as they do not require impellers to transfer the oil. Positive displacement pumps use reciprocating or rotating parts, creating pressure to transport fluid. A diaphragm pump is an example of a positive displacement pump.

These pumps are ideal for high-viscosity fluids that transport at higher pressure but at a lower rate. You can use them during the upstream phase of the refinery. These units are more compact, allowing the high-pressure ratio to increase. This unit’s construction and design make this pump an affordable option for many people. However, these pumps are high-maintenance and louder than centrifugal pumps. They are less than ideal for applications requiring high flow rates.

Gear Pumps

A gear pump is another type of positive displacement pump that uses gears to transfer fluids. You can also use them to clean fluids as they pass between the narrow gear tolerances. These units have a discharge pip system with a relief pump to protect the pipe and pump from experiencing over-pressurizing. You can use gear pumps for chemical transfer applications.

There are two types of gear pumps. External gear pumps rely on an external spur gear to drive the internal gears. The internal gears allow non-lubricating fluids to pump through because they do not touch. Internal gear pumps use a shaft-driven drive gear.

Reciprocating Plunger Pumps

These pumps are prevalent in the gas and oil industry. Plunger pumps can pressurize liquid in an enclosed cylinder. They use the piston and plunger reciprocating action to move the fluid to a pipe system. You can expect constant flow rates during the process because these pumps remain consistent despite the pressure at any given speed. These pumps require a relief valve in the discharge piping system to prevent overpressurizing in the piping and pump system. You can often find these pumps in applications like saltwater disposal, descaling, oil and gas pipelines, well services and hydraulic fracturing.

Progressive Cavity Pumps

These pumps move liquids with a turning rotor. This process creates a series of small, fixed-shaped chambers that move through the unit. The flow rate remains constant regardless of the system pressure, though it is normal to experience flow slippage at higher pressures. You can use these pumps for high-viscosity applications when you do not need to mix the pushed fluid. They can also handle solids, making these pumps ideal during sludge and slurry transfers and wastewater treatments. These pumps also need a relief valve to prevent overpressurizing in the piping and pump system.

Shop Centrifugal Pumps From Louisiana Chemical Equipment Company

At Louisiana Chemical Equipment Company, we’re proud to be a leader in our industry. We purchase and sell quality, used equipment for businesses in the refineries, industrial chemical plants and more. We’re a trusted source of equipment and have been for more than five decades.

We offer more than 14,000 items, and you can easily browse our site to find what you need by searching specific categories within our 85 options. Throughout our catalog, you can find silos, sifters, heat exchangers, pumps, tanks and much more.

Our equipment is available for relocation and inspection, so you can be sure to find the best pieces for your needs. You can easily browse our inventory, including centrifugal pumps for oil and gas industry applications. You can also contact our experienced team or complete a purchase request to suit your needs.

Linked Sources:

https://www.lcec.com/commerce/misc/equip_search.jsp?category_id=1101&czuid=1684162033011

https://www.lcec.com/commerce/misc/equip_search.jsp?category_id=1102&czuid=1684162033011

https://www.lcec.com/commerce/info/contactinfo.jsp

https://www.lcec.com/commerce/customer/purchaseRequest.jsp

https://www.lcec.us/featured-items/

Unlinked Sources:

https://www.daepumps.com/resources/types-refinery-pumps-used-oil-gas-downstream-operations/

https://ifsolutions.com/types-of-pumps-in-oil-and-gas-industry/

https://cbeuptime.com/types-of-pumps-used-in-the-oil-and-gas-industry/

https://www.lcec.com/commerce/misc/equip_search.jsp?category_id=1102&czuid=1684162033011

https://visserssales.com/pros-and-cons-of-progressive-cavity-pumps/

Louisiana Chemical Equipment Company • Toll Free +1-866-289-5232 • International +1-281-471-4900

+1-225-923-3602 • sales@LCEC.com • plants@LCEC.com

Louisiana Chemical Equipment Company, L.L.C.

offers an extensive range of quality chemical process equipment and Complete Chemical Plants with competitive pricing.